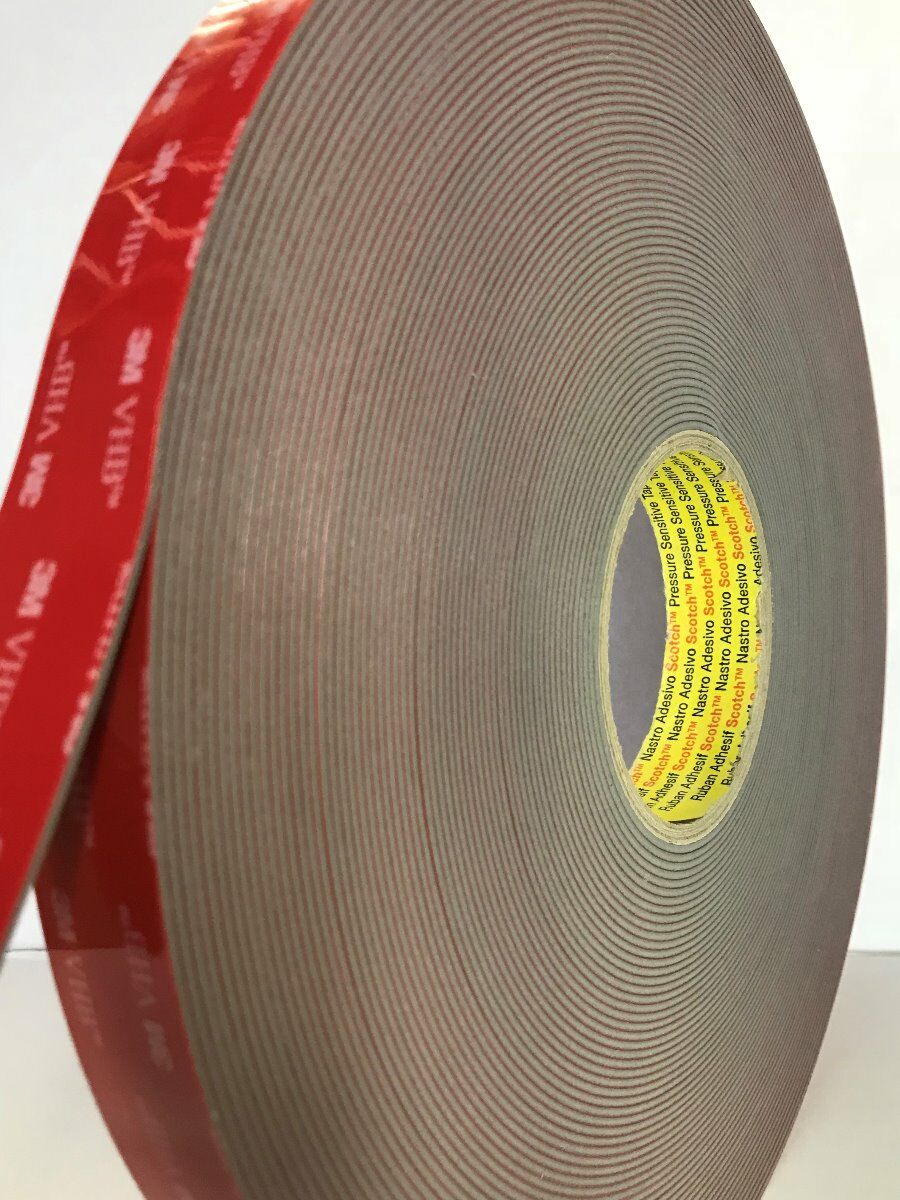

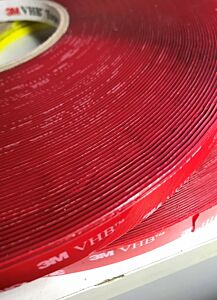

3M GPH Series VHB Tape (High Temperature Double Sided Tape)

We supply 3M GPH (General Purpose High Temperature) VHB Tape Australia Wide

3M VHB Tape - GPH series is a permanent bonding solution that can replace traditional mechanical fasteners and liquid adhesives in challenging, high temperature applications. It uses a conformable, acrylic foam core to provide a good balance of strength and conformability. 3M VHB Tape - GPH series has Excellent Temperature Resistance (Up To 230c Short Term, 150c Long Term) making it ideal for permanent bonding where high temperature tolerance is needed, including applications that undergo a powder coat or liquid painting process.

Features of GPH High Bond Double Sided Tape

- Good adhesion to high and medium surface energy materials (metals, glass, plastics) as well as many coated or painted surfaces

- Excellent temperature resistance (short term 230˚C and long term 150˚C)

- Good solvent resistance

- High initial tack providing strong immediate handling strength

- Conformable foam offers good gap filling and stress relaxation

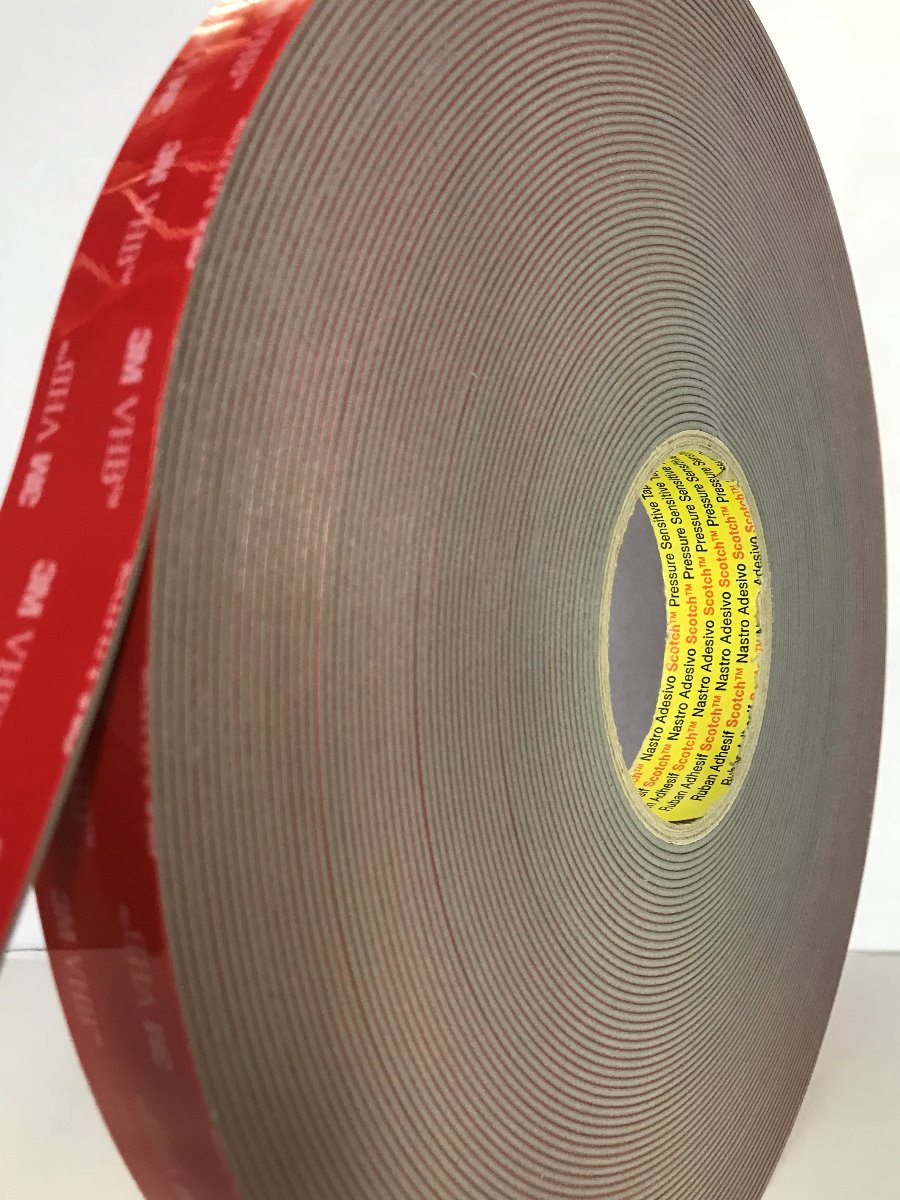

- Available in three different tape thickness's - (GPH-060) 0.6mm, (GPH-110) 1.1mm & (GPH-160) 1.6mm

- Each roll has 33 metres length

Main Applications For Our High Temp, High Bond, High Tack Double Sided Tape include;

- Any installations or products this tape is applied, that will be constantly exposed to prolonged high temperatures.

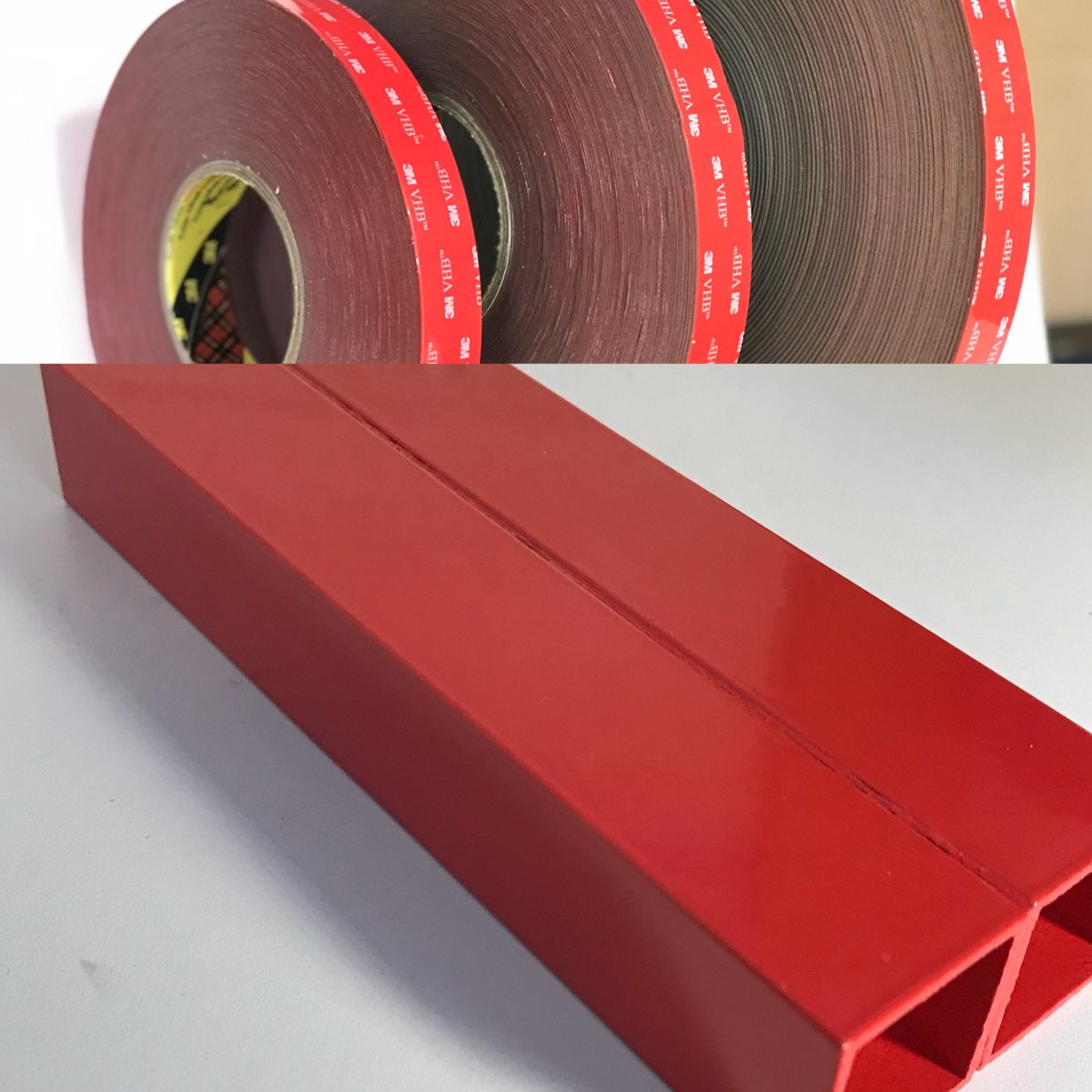

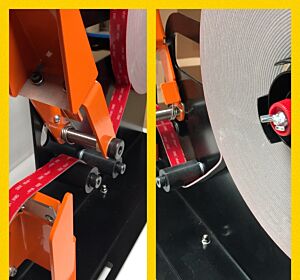

- To streamline manufacturing process's that previously D/S tape couldn't be applied to. An example of this is Powdercoating, where individual products would have to be powdercaoted first, before VHB - Very High Bond Tape could be applied. Now with the 3M GPH range of High Temperature Double Sided Tapes, Tape can be applied to your products pre powdercoating. Then put through the powdercoating oven.

- Products / Assets / Vehicles / Ships that previously had high temp areas where the only solution was welding or rivets, can now be applied with tape. eg - serial number plates in engine bays, any attachments on or nearby with hot temperatures.

- Structures / products exposed to high temperatures that previously could only be welded can now be produced / installed quicker using GPH Hi Temp double sided tape. Using GPH tape also will not cause panel distortion as what occours with welding

* For Large Quantities, Blanket Orders or Die Cutting of 3M GPH - GPH 060 (0.6mm thick) - GPH-110 (1.1mm thick) & GPH-160 (1.6mm thick) VHB Tape, Please contact us for Bulk Pricing *

3M VHB Tape GPH Series, general purpose high temperature, is a grey conformable double coated acrylic foam tape with a high initial tack and a soft foam. Its excellent temperature performance (up to 230c) enables bonding of materials in application with high operating temperatures. Further, its capability to bond to a wide variety of substrates makes it a good fit for multi material bonding. A great application for the GPH range of VHB tapes is product pre-assembly prior to going into baking ovens for powdercoating.

General procedure for applying 3M GPH Double Sided Tape Prior to Powder Coating

Generally the operating temperatures of powder coat plants range from 180°C for epoxy to 200°C for epoxy polyester and 220°C for polyester. The powder coat process varies considerably and no two plants are exactly the same, hence each application should be evaluated individually. However, in order to obtain the maximum performance from the tapes the following procedure should be observed.

- 1 Ensure the surfaces are completely free from grease, rust and oil by cleaning with VHB hIPA 300. Aluminum can be particularly difficult to clean due to the oxide layer but perseverance here is the key. The bond can be improved by cleaning, then abrading the surface with 3M 7447 Scotch Brite purple abrasion pad and then cleaning again cleaning with VHB hIPA 300. It is important to abrade in one direction if abrading.

- 2 Try to use as much tape as possible in each application. Remember the narrower the tape width, the quicker the heat will build up under the bond area which will reduce the holding capability of the tape during the process. Therefore stress on the bond line should be minimized by avoid direct loading on the tape.

- 3 Be aware of thermal expansion and mismatch especially when using the thinner tapes. Both of these will be particularly important at higher temperatures. So it is advised to use the thicker versions of the tape for longer sections to be bonded.

- 4 Apply pressure to the bond area and leave to dwell for at least ½ hour before the assembly is suspended on the powder coat line. This is critical, if the unit is suspended too early the bond strength will not have built up sufficiently and it will fail. Again, make sure that the loading on the tape is minimal and that the tape does not support the weight of the unit.

- 5 Try to ensure that there are no areas where moisture from the pre-cleaning process or air can become entrapped behind the tape, otherwise, during the drying process the moisture may expand and cause the tape to lift off. (i.e. tape not rolled down properly , mismatch etc )

- 6 When actually in the oven the tape should be exposed to high temperatures for no more than 45 minutes maximum ideally shorter. Most ovens have a cycle that is around 30 minutes. In the case 3M VHB GPH Series February 2017 of a 'static walk in 'oven an element of control must be introduced to ensure that the unit is not in the oven for too long.

- 7 When the unit is finished it must be allowed to cool completely before the bond is stressed. The tape is still soft when the unit is warm and it can be very easy to weaken the bond by unnecessary handling and failure will probably occur. Care should be taken not to twist large panels prematurely.

- Notes on the powder coat method There are two methods of automatic electrostatic powder coating systems, either paint charged or unit charged. In the case of unit charged systems, it is necessary to ensure that areas insulated by the tape are electrically connected to ensure an even charge over the entire the unit. In the case of paint charged systems it is unnecessary to electrically connect the entire unit , also the powder tends to bond to the edge of the tape leaving a 'filleted' attractive paint line, hence no tape is visible on the finished unit.

We supply 3M Very High Bond - GPH (High Temperature) Double Sided Tape to Sydney, Newcastle, Canberra, Brisbane, Melbourne, Adelaide, Perth, & right across Australia