The Ultimate Terminology Guide for Adhesive Tapes

The Ultimate Terminology Guide for Adhesive Tapes !

Here is the A - Z Terminology / Glossary of Terms for all areas of & around Adhesive Tapes

Types of adhesives:

There are several different types of adhesive coatings: Acrylic, Acrylic mass, Butyl,

Foam Cored Acrylic, Natural Rubber, Silicone, Synthetic Rubber.

Acrylic adhesive:

The most commonly used system for foam and double sided tapes as it is regarded as having very good long ageing properties, provides good UV & solvent resistance (check spec. sheet) and has good temperature resistance. There are some different types of acrylic adhesive often referred to as modified acrylic, aqueous acrylic, solvent acrylic. Acrylic adhesive is used with most high performance tapes but can also be found on the cheaper end packaging tapes which exhibit good long term performance when applied properly. Should be applied in temperatures from 15°C - 40°C.

Acrylic Mass:

Solid acrylic adhesive that exhibits high cohesive strength with high initial tack. The adhesive bond strength increases over time from initial installation. Elasticity of acrylic mass is ideally suited for applying to substrates that are exposed to expansion & contraction. Has excellent resistance to UV, weathering, solvents & extreme temperature variations from -30°C to +100°C.

Butyl adhesives:

This adhesive system exhibits high adhesive strength with low cohesive strength. Has excellent ageing characteristics & resistance to moisture & weathering. Ideally suited for sealing applications.

Differential Adhesive (Removable Adhesive);

This is a acrylic solvent based adhesive which can be removed cleanly for up to a couple of weeks (depending on the conditions it is exposed to) leaving no residue after it has been applied. Removable double sided tape has a permanent adhesive on the open side, & a removable adhesive on the closed (liner) side

Foam Cored Acrylic Mass:

Open weave foam impregnated with solid acrylic adhesive that exhibits high cohesive strength with good initial tack. The adhesive bond strength increases over time from initial installation. Elasticity of foam cored acrylic is ideally suited for applying to substrates that are exposed to expansion & contraction. Has excellent resistance to UV, weathering, solvents & extreme temperature variations from -30°C to +93°C.

Natural rubber: (rubber solvent)

This adhesive system is regarded as the best system for packaging tape and some double sided and masking tapes. This system offers moderate initial tack with very good adhesion offering a superior bond to a variety of virgin & recycled board and performing well in the freezer applications as well as hot humid conditions. Not suited to very long term bonding as the adhesive strength will gradually break down with age & yellow. Resistance to UV, weathering & solvents is fair. Should be applied in temperatures from 10°C - 40°C.

Silicon adhesive:

This adhesive system is fairly uncommon, expensive and used for specialized applications. It will withstand extreme temperatures over 200°C. and is the only adhesive that will stick to silicon coated paper (release liner on tape and labels) and is generally used for securing the end of the roll or splicing applications. This adhesive exhibits very low tack when first pulled off the roll.

Synthetic rubber: (hotmelt)

This adhesive system is commonly found on mid range packaging tape and some cheaper single & double sided tapes. This system offers good initial tack but is limited to short term less critical applications as the adhesive has limited long term performance. The adhesive is degraded by UV light & should not be used in applications where the tape is subject to UV exposure. Resistance to solvents is poor and the adhesive does not perform well in high temperatures it can also lose some of its tack in cold conditions. Should be applied in temperatures from 15°C - 30°C.

Types of backings:

There are several different types of backings: Acetate, Cotton Cloth, Filament Reinforced,

Metallic, Polyolefin, Polyester, Polyethylene, Polypropylene, PVC, Rayon & UPVC.

Acetate Film: - Transparent film that is moisture resistant.

Cotton Cloth Film: - Offers very good flexibility & conformability whilst retaining its tensile strength. Can be coated with various adhesives & torn by hand.

Filament Reinforced Film: - Commonly associated as a filament tape it offers excellent tensile strength. Glass fibers give tape strength & can not be torn by hand. Can be coated with various adhesives on an OPP or Polyester film.

Metallic Film: - Usually made from aluminum the film has excellent insulation & flame retardant prosperities & resistance to solvents. Can be reinforced with woven material to provide extra tensile strength.

Polyester Film: - Synthetic film with high tensile strength to which different adhesives can be coated. Versatile film that can be used inside or outside with excellent resistance to moisture, abrasions, chemicals & solvents depending on type of adhesive coating. Film has low stretch characteristics.

Polyethylene Film: - Tough film that works well @ low temperatures with good tensile strength to which different adhesives can be coated. Film that can be used inside or outside with excellent resistance to moisture, abrasions, chemicals & solvents depending on type of adhesive coating. Exhibits good isolation properties.

Polyolefin Film: - Economical film with a matt finish to which different adhesives can be coated. It can be applied easily by hand. Softer & more flexible than OPP, this film offers silent unwind with higher abrasion resistant than OPP films & is generally biodegradable. Film can be printed on.

Polypropylene Film (BOPP): - BOPP = Bi axially oriented polypropylene (same stretch along and across the film). Economical film to which different adhesives can be coated. It can be applied easily by hand or machine roll form. This is the most commonly used backing material for packaging tape & is generally biodegradable. Can be metallised for decorative & other specialist applications. Film can be printed on.

Polypropylene Film (MOPP): - MOPP = mono axially oriented polypropylene (tensalised along the length of the film ensuring no stretch). Economical film to which different adhesives can be coated. It can be applied easily by hand or machine roll form. This is mainly used for strapping / palletising tapes as the film has no stretch.

PVC Film: - Plasticised Poly-Vinyl Chloride. Softer & more flexible than UPVC, this film is highly conformable & also exhibits excellent resistance to abrasions, oils, chemicals & solvents. Film offers silent unwind with higher abrasion resistant than OPP films & offers reduced stretch. Film can be release coated for easy unwind & is not biodegradable, therefore not considered to be environmentally friendly. Generally suitable for hand applications only.

Rayon Cloth Film: - Offers very good flexibility & high tensile strength. Usually coated with polyethylene the cloth is resistant to chemicals, solvents & weathering. Can be coated with various adhesives & torn by hand.

UPVC Film: - Unplasticised Poly-Vinyl Chloride. A tough durable film having excellent resistance to abrasions, oils, chemicals & solvents. Film offers silent unwind with higher abrasion resistant than OPP films & has low stretch. Film is hard to unwind & is not biodegradable, therefore not considered to be environmentally friendly. Can become brittle in cold conditions. Generally suitable for hand applications only. Film can be printed on.

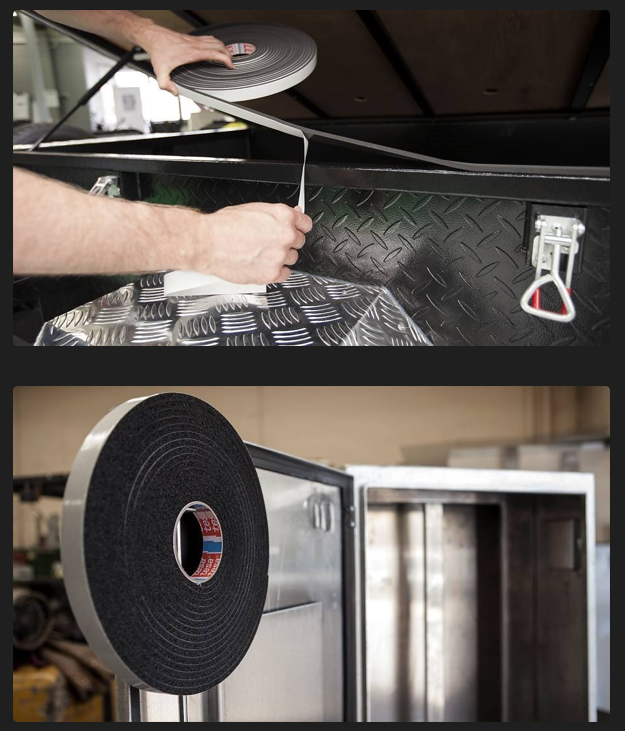

Types of foams:

There are several different types of foams: EPDM, Neoprene,

PVC, Polyethylene, Polyurethane & PVC/Nitrile.

EPDM; - Is a synthetic rubber produced from a mixture of ethylene & propylene. Foam offers very good weathering characteristics & resistance to low & high temperatures. Suitable for outdoor use.

Neoprene; - Is generally available in single sided form because the cell face does not lend itself to lamination. Offers very good weathering characteristics & ozone resistance. Suitable for outdoor use. Neoprenes are self extinguishing & exhibit good resistance to hydrocarbons.

PVC; - Is good, general purpose foam with favorable aging characteristics & offers good resistance to UV light, fungi & weathering. Available in different forms from single to double sided, open to closed cell, super soft to hard density. Usually coated with acrylic adhesive they are long aging & do not harden or become brittle in sunlight. PVC foam is generally flame retardant under compression. The presence of plasticisers in the material may migrate into the product being applied to. Can be laminated with other substrates for specialised applications.

Polyethylene; - Is generally used for bonding & mounting applications. Being very conformable they offer economical advantages when offered in low densities. Available in different forms from single to double sided, soft to hard density. Usually coated with synthetic rubber adhesive & occasionally acrylic. Foam ages well & is resistant to UV light, fungi & weathering. It does not contain plasticisers & can be used in applications where it may come in contact with plastics. Due to its cellular make up this foam should be limited to maximum compression rates of 20%, after this rupture may occur & the foam will not recover.

Polyurethane; - Is generally used because of its low cost. Available in different forms from single to double side, soft open cell to highly compressed to form high density foams. Soft open cell foams have poor aging characteristics, become brown when exposed to UV light, weathering & eventually crumble to dust within a few years. High density offer better aging characteristics & resistance to chemicals, fungi & weathering.

PVC/Nitrile; - A general purpose closed cell foam that exhibits similar characteristics to EPDM & Neoprene’s. Usually coated with acrylic adhesive they are long aging & have good resistance to weathering & high temperatures. Foam is generally flame retardant under compression.

Below are terms that are used when discussing all areas concerning adhesive tapes

Abrasion Resistance: - The ability of a tape to withstand rubbing or wearing & still function satisfactorily.

Adhere: - A word used to describe what an adhesive will do when applied to a particular surface. i.e. Most tapes won’t adhere to that surface.

Adhesion: - Is the bond produced between a pressure sensitive adhesive & the surface it is in contact with. Adhesion build up: Increase in the adhesion value of a pressure sensitive adhesive tape, after it has been allowed to dwell on the applied surface.

Adhesive: - Any material that will usefully stick two or more objects together by surface contact. Can also be referred to as “Mass”

Adhesive Transfer/Residue: - Adhesive that is pulled away from the tape & remains on the surface to which the tape was applied or adhesive left behind on the backing when unwound.

Application temperature: - Recommended temperature (°C) range at which a pressure sensitive tape should be applied in order for the tape to perform successfully.

Bleeding: - Some tapes that have a thick or heavy coat weight of adhesive can sometimes bleed adhesive from the edge of the roll.

Bond: - The adhesion of a pressure sensitive adhesive tape to the surface to which it has been applied. Bond strength: The amount of force required to separate the joined surfaces.

Bobbin Wound Rolls; - Bobbin Wound Rolls of tape are rolls that have thousands of metres of tape rolled onto them, designed for factories with high volume production,where the tape is generally applied to the product at point of manufacture

Carrier: - A product that can be used to coat adhesive to either one or both sides to make a tape. A carrier can be filmic, paper, tissue, cloth and foam.

Chemical resistance: - Ability of a tape to withstand exposure to chemical substances & still perform satisfactorily.

Cleaning: - The surface to which a tape is being applied should be cleaned prior to application to remove any contaminants. Preferable cleaning solution is Isopropanol. The following cleaners should never be used as they tend to leave a surface film which affects adhesive bonds: Turpentine, Methylated Spirits, Thinners, Kerosene, Prep sol, Citrus Cleaners, Window & Household Cleaners.

Cleavage strength: - Force impact on the upper/leading edge of the bonded area as if one is trying to lever the tape away from the bonded surface due to load pulling on the object.

Coated Cloth Tape: - Hand tearable fabric that is traditionally coated with a coloured waterproof polyethylene film to the top layer of fabric & adhesive to its underside. The type of adhesive can vary.

Coating: - Usually a liquid used to form a covering film over the tapes exposed surface. Can be to decorate (coloured) or protect the surface from destructive agents or environment.

Cohesion: - The internal strength of the adhesive & its ability to resist delaminating. Good cohesion is necessary for clean removal. Softer adhesives have lower internal strength where harder adhesives exhibit higher internal strength.

Cold flow: - The tendency of an adhesive to act like a heavy, viscous liquid over a long period of time resulting in oozing & increased adhesion.

Conformability: - The ability of a tape to yield to the contours of a curved or rough surface.

Creep: - The slow movement of the adhesive or backing under stress/load.

Creped: - Paper that has small folds to provide stretch ability & conformability, normally associated with masking tapes.

Curling: - The tendency of a tape to curl back on itself when unwound and allowed to hang from the roll.

Delamination: - The separation of a material into layers, in a direction approx parallel to the surface.

Dielectric strength: - Measurement of the electrical insulation properties of a films ability to resist an electric current passing through the tape.

Die Cut / Die Cut Tapes; - This is Adhesive Tapes which are converted, or Die cut to different shapes & sizes. Die Cut tapes are used to streamline manufacturing process's, aswell as being put into instalation kits for products that are sold to be installed at a later date

Double sided tapes: - A product consisting of a backing material (carrier) to which the same or different adhesive can be applied to each side. The carrier can be made either of tissue, paper, cloth, and filmic carriers such as: Polypropylene, PVC, Polyester or foam carriers such as PVC, EVA, Neoprene/EPDM Polyethylene & Polyurethane.

Dwell time: - Is the amount of time required for an adhesive to cure & reach its maximum bond strength. The bond strength of some adhesives actually increases over time from initial installation. Dwell time is influenced by several factors such as: surface temperature, climatic conditions i.e. winter vs. summer, surface energy & pressure. It is preferable to allow as much time as possible for the tape to cure before any stress is placed on the tape.

Edge curl: - The peeling back or lifting of the outer edge of a tape after application.

Elastic Memory: - The tendency of a tape backing to attempt to return to its original length after being stretched or elongated.

Elongation: - The distance a tape will stretch lengthwise before breaking.

Extended Liner / Fingerlift Tape; - Extended Liner or Fingerlift tapes are tapes that the liner extends over the adhesive so it is easy to remove the liner when you are using / sealing another surface with the other side of the tape. Examples of Extended Liner / Fingerlift tapes are Courier Bags, envelopes, etc

Fish Eye: - A small round or oval deformation in an adhesive or coating usually caused by trapped air between the layers of the tape on the roll.

Flagging: - The lifting or peeling away of the end of a tape particularly in spiral-wrap applications.

Flame resistance: - The ability of a tape to withstand exposure to a flame. Flame resistant (fire-retardant self extinguishing) materials will burn when exposed to flame, but will not continue to burn after the flame is removed.

Flame retardant: - A material that resists burning when exposed to a flame.

Flatback: - Used where high strength of backing is required so tape won’t split or rupture under load as it has not been creped. Usually has high degree of tensile strength.

Flexibility: - The ability of a tape to be freely bent or flexed when applied.

Fluting: - Distortion of a roll of tape in which the layers no longer form a circle.

Gapping: - Openings between layers of tape within a roll.

Ghosting: - Transfer of images or print from the surface of the roll.

Gloss: - A shiny finish on a smooth surface such as vinyl or custom printed tapes.

Hand tearable: - Ability of the tape to be torn by hand without the aid of a sharp instrument.

Heat resistance: - The ability of a tape to withstand exposure to specified temperatures after it has been applied to a surface.

Impact/shock resistance: - The ability of a tape to resist sudden pulls or shocks.

Insulation resistance: - The ability of a tape to resist the flow of electric current across the backing surface.

Kraft paper: - A sulphate impregnated wood pulp paper.

Lamination: - A combination of two or more similar or dissimilar materials that function as one backing.

Lay flat: - The ability of a tape, once applied to resist curling or flagging.

Logs of Tape; - Adhesive Tapes come in Logs, generally 1200mm to 1500mm wide, & are either slit down to the sizes required, or Die Cut to the shapes required.

Lifting: - A situation where a section of tape has pulled away from the surface to which it was applied.

Liner: - Material that acts as a barrier between tape & adhesive to prevent it sticking on to itself.

Low surface energy: - This is a surface that does not readily accept an adhesive. In this instance you will need to apply adhesion promoter (primer) to improve the bonding of substrate.

Mastic / Self Amalgamating Tape; - Mastic tapes are designed to be stuck onto themselves around pipes,cables,etc. When Mastic / Self Amalgamating Tapes are applied, the fuse onto themselves forming a barrier to insulate / protect what they are adhered too.

Melt point: - Adhesives do not have a specific melting point; they gradually soften as temperature increase & will reach a point where the load can no longer be supported.

Memory: - 1. Filmic tapes ability after being unwound & stretched to return back to its original length. 2. Foam tapes ability to recover to it’s original height after being compressed and during compression the memory of thefoam must excerpt an outward force on the surface compressing it to maintain a seal.

Memory set / compression set: - The collapse or rupture of the cells (air pockets) in a foam tape after having been compressed too much, resulting in the foam being unable to return to its original height, in this situation the seal could eventually fail.

Microns: - Tape strength is often measured by its film thickness in microns (1um = 0.001mm)

Migration: - The movement over a long period of time of an adhesive ingredient from the tape adhesive to the applied surface.

Moisture resistance: - The ability of a tape to withstand exposure to water or moisture & still function properly.

Non-woven carrier: - Backing material composed of directionally or randomly oriented fibers.

Oozing: - Squeezing out of adhesive from under the backing of the tape in its roll form, resulting in the edges of the roll becoming tacky.

Operating temperature: - Temperature range in which the tape will perform once it has been applied to a surface.

Peel strength: - Force required to break the bond between a flexible tape & a surface when peeled back (standard angle of 180°).

Penetration resistance: - Ability of tape to resist slow puncture under pressure.

Pinhole: - A very small hole that may permit the passing of light, moisture or electric current.

Polyethylene: - An extruded, tough stretchy film having limited temperature resistance but good moisture barrier properties. Can also be used as a foam backing.

Polypropylene: - A polyolefin plastic similar in properties to polyethylene but with higher temperature capability & greater strength.

Pressure sensitive adhesives: - Is an adhesive that requires direct pressure via hand or applicator to activate adhesive bond between surface & tape. The higher the amount of pressure applied the greater the initial bond. Adhesive is more aggressive when being applied at room temperature. The bond strength is dependent on the degree of wetting out achieved during this process. Please note that the bond being formed is influenced by various factors such as: type of adhesive, time, temperature, pressure & surface energy.

Primer: - Used mainly where a low energy surface is encountered. Without the use of a primer (adhesion promoter) the bond achieved may not prove successful. See our adhesion promoter.

Quick stick: - The ability of a tapes adhesive to adhere to a surface with light or no pressure.

Release coating: - Coating applied to the outside face of a tape to provide easy unwinds to prevent delaminating or tearing.

Release liner: - Sheet of material covering the adhesive side of the tape. Liner is removed to expose the adhesive prior to application.

Residue: - Adhesive left on a substrate when tape is removed.

Saturation/Impregnation: - Addition of materials to a tapes backing to improve its physical characteristics such as resistance to moisture, solvents or chemicals.

Self wound: - Where a roll of tape is wound onto itself without a release liner.

Self Fusing; - See Mastic Tapes for description

Shear strength: - Forces impact parallel to the bonded area as if one is trying to slide the tape off the item. As temperature is increased both shear & adhesion strengths are reduced & risk of failure increases.

Single faced: - Adhesive is applied to one side of the tapes backing only.

Slivering: - Occurs when a tape tears or breaks into small pieces during unwind or removal from the applied surface.

Solvent: - Chemical substance capable of dissolving another material.

Stain resistance: - Ability of a tape to not discolour the application surface.

Strength & Stress factors: - When bonding any items to one another you must consider what load factors will be exerted on the tape in the form of: cleavage, peel, shear & tensile forces. A bond can be influenced by one or a combination of these factors simultaneously.

Surface Condensation: - Occurs when surface to which tape is being applied is cold, it is recommended that the surface be artificially heated to remove any moisture before applying tape.

Surface energy: - Adhesion strengths are influenced by attraction of two molecules to each other, hence the higher the surface energy the greater the attraction.

Tack: - The degree, to which the adhesive feels sticky or highly tacky, increases with temperature.

Tape: - Product consists of a backing carrier to which an adhesive is coated either single or double sided. The carrier comes in different forms which gives tape different performance characteristics in: strength, abrasion resistance, colour, thickness & resistance to chemicals & temperatures depending on the carrier chosen.

Tape backing: - Is backing of the tape that the adhesive is coated to.

Tearstrip Tape; - Tearstrip tape is tape that you come across on products that usually have a little red "pull cord" exposed, to tear along the packet to open up the packet. The "little red cord" is the actual tearstrip tape which is applied during production of the packet, etc

Telescoping: - A sideways sliding of the tape layers while in its roll form.

Temperature: - Variations affect the physical characteristics of the adhesive, general rule of thumb: Low temps = reduced adhesion, Moderate to high temperatures accelerate the adhesive bond rate when being applied & improves the overall performance of pressure sensitive bond. A bond formed at low temperatures will require longer period before full bond strength is achieved.

Tensile strength: - Forces impact perpendicular to the bonded area as if one is trying to break the bond by pulling away @ 90° angle.

Transfer tapes: - Adhesive coated directly onto release liner without a carrier base, an easy way to describe this product would be glue on a roll, often referred to as unsupported double sided. Designed to aid in the assembly of low surface energy materials where high wetting out is required. Consists of a layer of adhesive only & in some instances can be reinforced with fibers or tissue to give it strength. This results in the tape being all adhesive & offers very good contact adhesion to surfaces. Some transfers can be applied via an ATG gun (Adhesive Transfer Gun).

UV resistance: - Ability of a material to withstand extended exposure to sunlight without degradation, hardening or discolouration.

Unwind force: - Force required to remove tape from the roll.

Wetting out: - This has nothing to do with making the surface wet it is the ability of an adhesive to flow uniformly over the surface to which it is bonded. Wet out is influenced by the amount of pressure being applied & nature of adhesive being used. Soft adhesive flow into grooves & uneven spaces.