Tape Supplies for the Automotive Industries

Embossing & Tape Supplies is proud to be major distributors of all 3M, BDF (Tesa), Husky, and Stylus tapes, with a huge product range for the automotive industry.

Going all the way back, South African cavemen used an adhesive layer of tree sap and red ochre to protect cave murals almost 70,000 years ago. Early adhesive tapes that age back hundreds of years ago, could magnify the longevity of paintings and buried kings far beyond the effort it took to apply them.

This trend of Automotive tapes has continued into the 21st century. Mechanical fasteners like screws, clips, and bolts just haven’t improved over time. The automotive industries face ever-increasing pressure to:

- Increase rigidity

- Minimise maintenance

- Streamline assembly

- Reduce weight

- Eliminate noise

- Improve longevity

Embossing & Tape Supplies have high-quality specialty and industrial tapes for an extensive range of industries, with a solid reputation for quality service and quality products such as automotive tapes. Automotive adhesives are often required for limited combinations where welds and screws won’t create ideal bonds. Simultaneously switching assembly steps over to automotive tapes has numerous collateral benefits, while lowering cost and increasing line productivity. Adhesives & Sealants Industry (ASI) provides a combination of value adds of PSAs for more modern vehicles.

- Bond securely and immediately to a host of substrates

- Eliminate time-consuming procedures and cumbersome equipment

- Are easy to handle and can be placed cleanly and accurately

- Integrate smoothly into automated processes and maintain stability and integrity during processing

- Allow converters to produce complex die cuts and diverse shapes

- Are safe in the workplace

- Eliminate the need to drill or machine parts—as is required with mechanical fasteners

- Eliminate the handling, mixing, or disposing of wet chemicals

Key Focuses For Automotive Tapes

Automotive tapes serve three key focuses or purposes, however each one plays in many forms and areas of the vehicle. The three key focuses include:

To Bond - Which contains two surfaces together or fastens components to substrates.

To Cover - A surface and alter its appearance, transparency, or texture to the desired finish.

To Protect - A surface from abrasion, impacts, moisture, chemicals, vibrations, or other threats.

Each of these key focuses is shown more specifically in niche areas like dashboard emblem mounting tapes (to bond), exterior chip-guard tapes (to protect), and paint replacement tapes for door sashes and frames (to cover). What benefits all three purposes is that they improve the value of the vehicle.

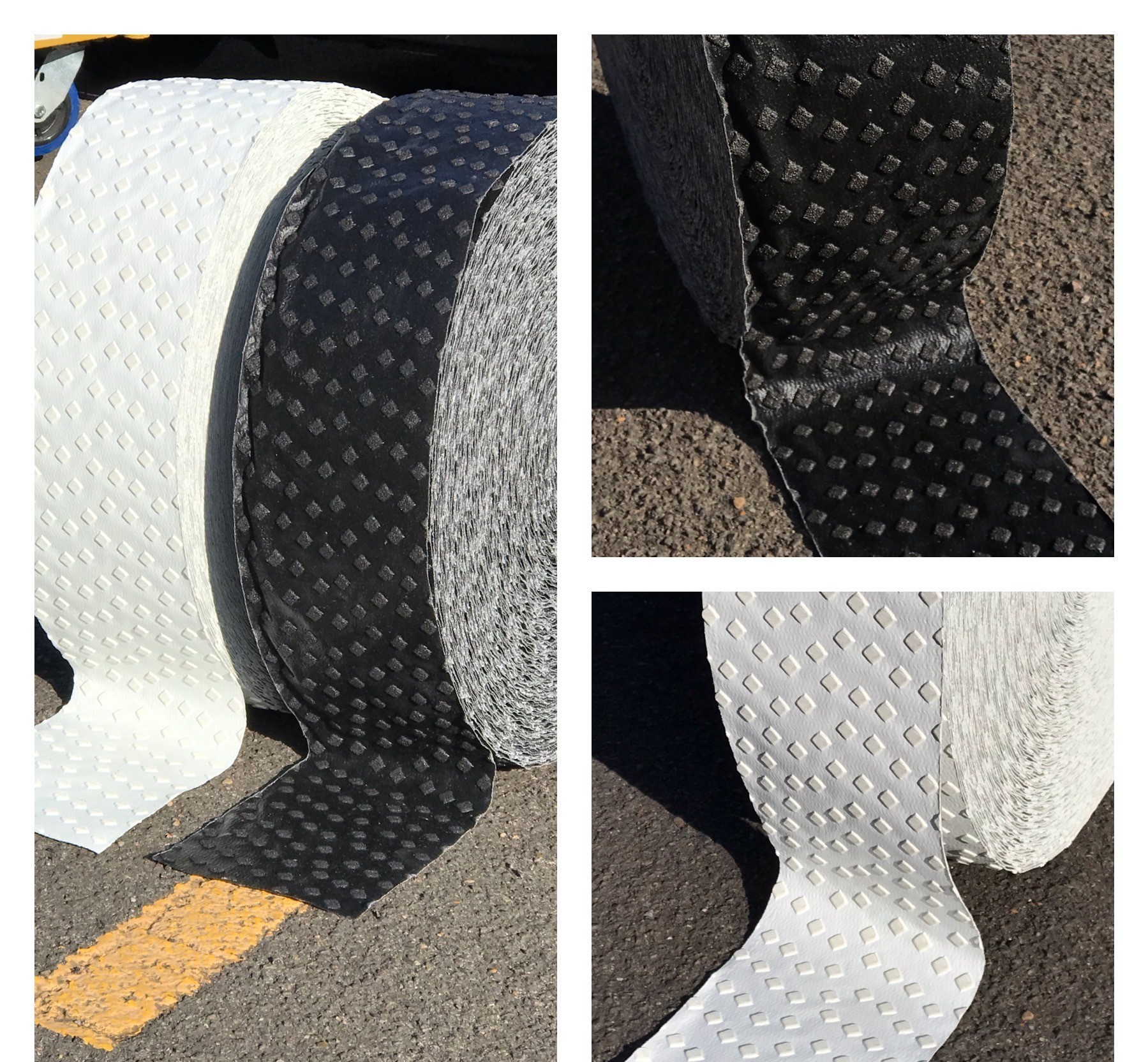

Anti-Chipping

Anti-chip tape can be deployed to protect high-impact areas of the vehicle from the potential hazards of the road. Sand, rocks, mud, splattered bugs and other debris are a usual cause for scuffs, paint chips or scratches in areas such as:

- Side Mirrors

- Front bumper

- Hood

- Headlights

- Fenders

A barrier of invisible anti-chip tape will outperform more difficult and expensive solutions like liquid ceramic coatings. Because these pressure-sensitive adhesives are also simpler to apply, anti-chip tapes increase value in assembly. The best tapes consist of numerous layers with unique functions: a hydrophobic, self-healing elastomeric clear coat, a durable (poly)urethane layer that absorbs impacts, and an invisible acrylic adhesive layer. The longevity these tapes provide to painted surfaces, coupled with their ability to self-heal, improve the overall quality of your design.

Anti-Vibrations

Vibration reduction is a major opportunity for automotive tapes to add value in modern vehicles. Additionally, they can solve all sorts of problems in automotive design. Double-sided polyurethane and acrylic foam tape supplies a vibration-damping barrier between bonded substrates which diffuses energy that could easily damage parts or create squeaks and rattling sound to your vehicle. Single-sided versions also make excellent liners for cup holders and other areas of the cabin inside modern vehicles.

Structural Bonding

Increasing number of non-steel materials used in modern vehicle assembly continue to make automotive tapes valuable to the market. Some Individuals find that mixed materials in vehicle bodies are a challenge for traditional fasteners. Whether it’s galvanic corrosion (steel/aluminium), low-surface energy (thermoplastics like polypropylene or polyethylene), or disparities in coefficients of thermal expansion (sometimes abbreviated CTE), automotive tapes are up to that challenge.

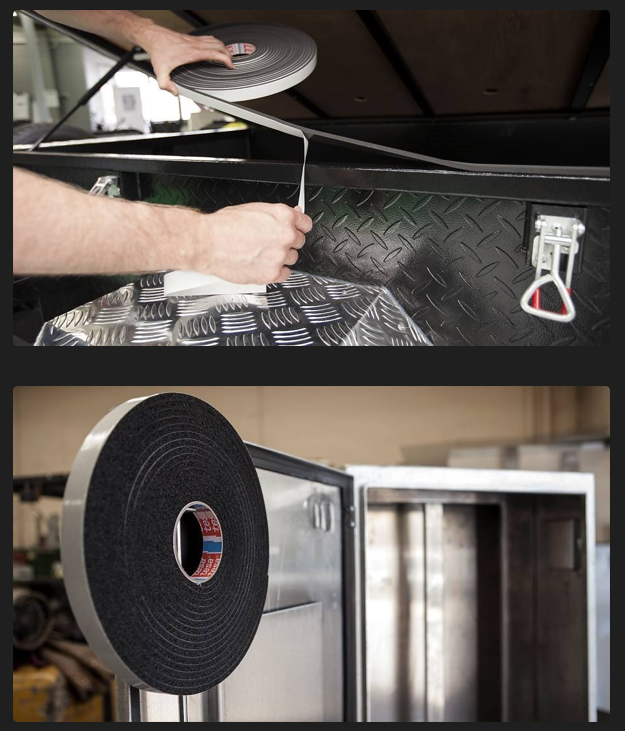

Cushioning

Embossing & Tape Supplies provide foam tapes for the automotive industries that can be used for reducing impacts, stresses and pressure to both interior and exterior areas of the vehicle. They’re generally used:

- Within the luggage rack and surface of the roof to cushion loading impacts.

- Around the door, trunk, and hatch frames to absorb closing shocks.

- As cushioning liners in cup holders or consoles that increase grip while absorbing impacts of deposited objects.

- For gas tank straps and pads that provide shock absorption and protect against friction wear.

Automotive flexible foam tapes also make excellent, forgiving seals that keep moisture, dust, wind noise, and weather from penetrating doors, windows, trunks, and sunroofs.

Mounting

A number of small components need to be mounted in a vehicle both interior and exterior. Automotive mounting tape is made with polyurethane (PUR) foam or acrylic foam to cater to the needs of the project. PUR foam cores have incredible tensile strength, ideal for rapid emblem mounting, whereas acrylic foams have better ductility and flexibility to accommodate differing CTEs while maintaining a strong bond over a larger area.

How Automotive Tapes Add Value

Likewise, every use or motive case for automotive tapes adds value in all the three manners or examples below. These advantages provide applications and new uses to standardised in the industry every year.

Cut Costs

Automotives tapes are supplied at a cheaper labour cost than most welded metal-to-metal bonds, due to required training, inspections, certifications and flaws that are hard to detect in QA. Automotives tapes take the slightest training to apply and result in high quality with a lower cost of production. Additionally, savings rises up as reliance on expensive tools including drills and painting equipment. Another tape that cuts cost is Pressure-sensitive tape which is really easy to apply to vehicles. These tapes take up less production space as well eliminating separate areas for painting, curing and priming.

Improve Rigidity

Rigidity is a common natural byproduct of pressure-sensitive automotive tapes which contract the full surface area between substrates. Fasteners essentially have periodic punctures that accommodate both the substrate strength and overall vehicle rigidity. The stress concentration of fasteners can even weaken the assembly, causing elements to buckle or tear more easily than tapes that disperse force along the whole bond.

Reduce Weight

Automotive tapes fit neatly into that future—particularly the double-sided varieties. Their 2019 market research report attributes automotive tape growth to increasing substitution of metal fasteners in automobiles due to increased affinity towards lightweighting. Research has found that a 10% decrease in automobile weight can improve fuel economy by around 8%. Moving aways from conventional mechanical fasteners cuts down automobile weight, while simultaneously maintaining cost and saving energy.

Save Time

The patience time of epoxies, glue and paints slows down production. Pressure-sensitive tapes take no time at all when applying it immediately. This makes it a lot quicker for workers or customers to use which accelerates line times and adds value. Quicker bonding techniques with products that are lightweight reduce the physical labour of human workers, increasing their physicality and productivity in the given time they need.

Values Matter More Than Price

Comparing prices or negotiating in the automotive industry are often price-centric. The key element of what matters more is the total value that is represented by the component or the adhesive solution. Automotive tapes have rapidly spread in usage throughout today's century of modern vehicles due to a number of opportunities they represented to cut all cost and add value.

Boost Durability

Additionally, some individuals insist that some common tapes are a weaker solution than normal materials like nuts and bolts. Adhesion isn’t the only way automotive tapes boost durability, although clear protective tapes add longevity to components and thereby add more value to the original prices given.

Contact Embossing & Tape Supplies For More Information

Embossing & Tape Supplies are distributors for the major tape companies in Australia, including 3M, Tesa, Stylus, Husky, Venture, PPC & many others with access to their worldwide technical resources. We are based in Sydney and deliver Australia wide, including Melbourne, Brisbane, Perth, Adelaide, Hobart. Our Team here at Embossing & Tape Supplies are the experts in all types of Adhesive Tapes like Automotive Tapes. We have a combined knowledge of over 80 years & have been established since 1974.

Contact us today at (02) 9526 2055.