What To Know About Adhesive Tapes & Low Surface Energy Plastics

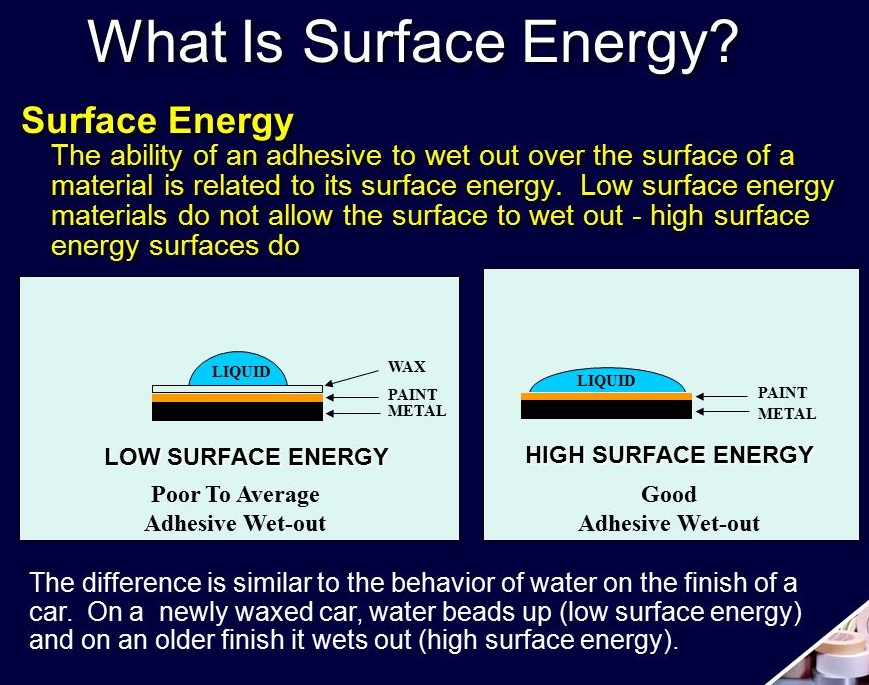

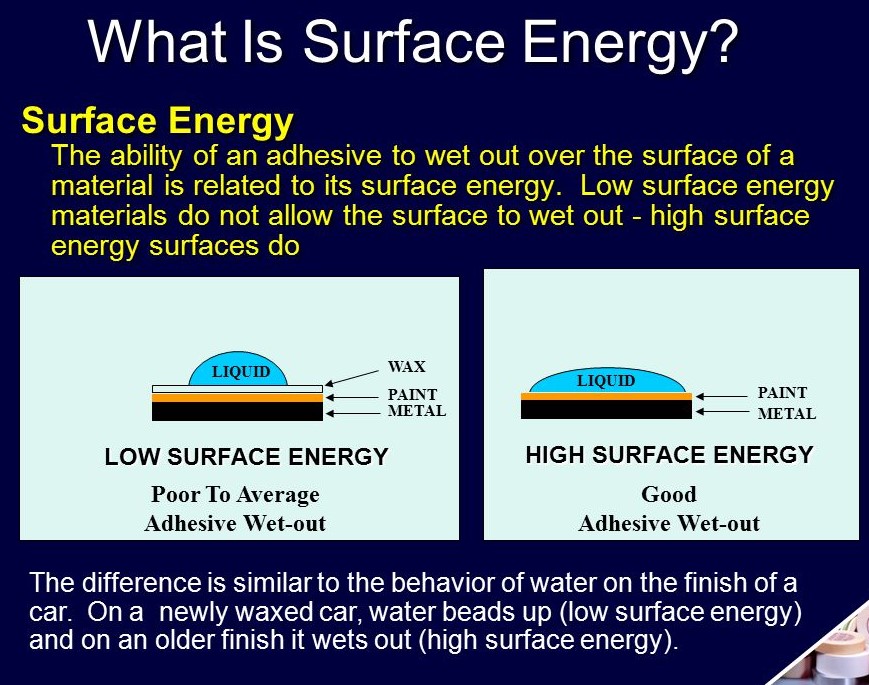

If you have trouble finding a tape to stick to plastics, there is a good chance they are Low Surface Energy (LSE). Here is a quick explanation on LSE, MSE & HSE plastics, which tape will work with what.

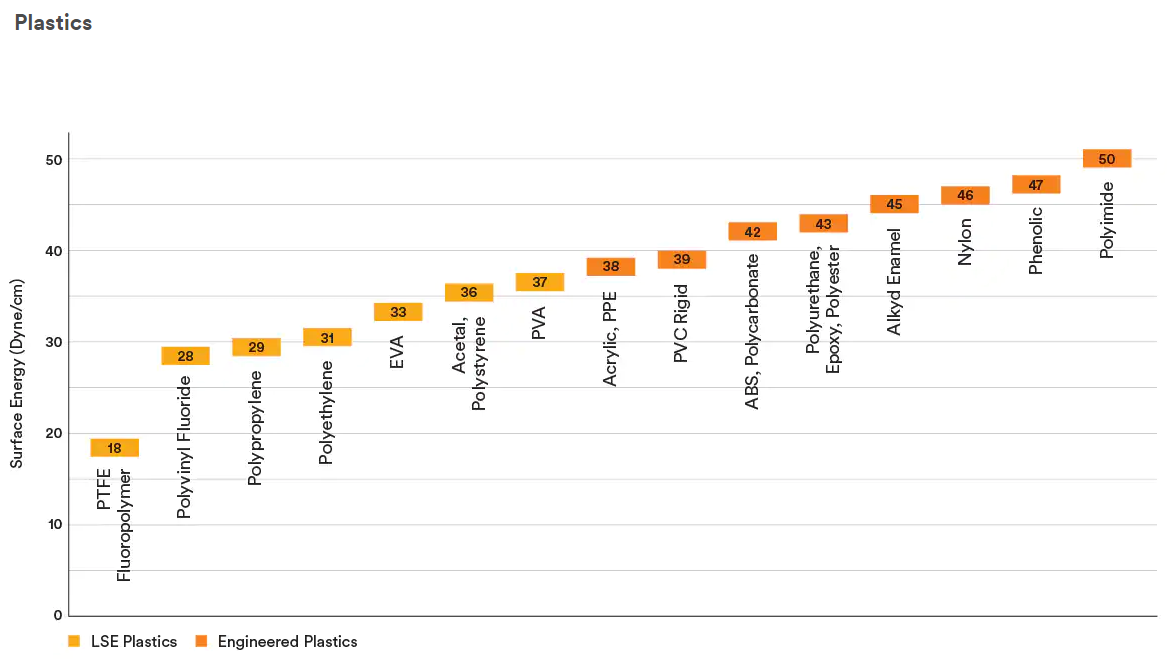

Firstly - Surface Energy is measured as dyne per centimeter. This is a unit of force. A dyne is defined as the force required to accelerate a mass of one gram at a rate of one centimeter per second squared. A dyne per centimeter is the unit traditionally used to measure surface tension and interfacial tension. The lower the Dyne/cm, the lower the surface energy, which makes it harder for adhesive tapes, double sided tapes to adhere to. The higher the Dyne per cm, the more friendlier the surface is for tape to be applied to

Below is a brief explanation of the different types of surface energy that different products are;

High Surface Energy

Molecules on the surface are so strongly attracted to each other that they will very happily be attracted to liquid molecules as well. As a result, these materials are relatively easy to wet out and, in turn, to bond. High surface energy materials have surface energies on the order of 100s or 1000s of dynes/cm and include many metals and glass.

In Summary, most types of tapes can be applied to HSE - High Surface Energy Products

Medium Surface energy

Everything is relative. Somewhere between perfectly wet-out films and perfectly spherical droplets, we define medium surface energy. These are materials typically 36 dynes/cm up to about 300 dynes/cm. Many engineered plastics have surface energies in this range, as do natural materials such as wood, stone, concrete, polycarbonate, HIPS (high impact polystyrene), Acrylic, Nylons, ABS (acrylonitrile butadiene styrene)

In Summary, for double sided tapes, it is recomended to use either 3M 5952 VHB tape, or the 3M LSE - VHB series tape.

Low Surface Energy

Molecules on the surface of low-surface-energy materials are quite happy the way they are. There is very little attraction to any molecule, especially adhesive molecules. Materials with a surface energy below 36 dynes/cm are considered low surface energy. LSE Plastics are generally soft, low-density and have a low melting point. These low surface energy materials stick together and repel liquids, making them difficult for adhesive tape to adhere to. These include polyolefin plastics such as polypropylene and polyethylene as well as “non-stick” surfaces such as polytetrafluorethylene (PTFE), thermoplastic olefins (TPOs), thermoplastic elastomers (TPEs), composites, and polyester paints.

A good way to tell if a product is LSE - Low Surface Energy, if water is put on the surface, it will bead up

In Summary, you need tape specially designed for Low Surface Energy - LSE products, we have Scotchweld DP8005 Adhesive, + a range of High Bond LSE Tapes + 3M VHB - LSE range of Tapes that will do the trick for you

If you are having trouble with double sided tapes sticking to low surface energy, we have a range of LSE designed tapes available.

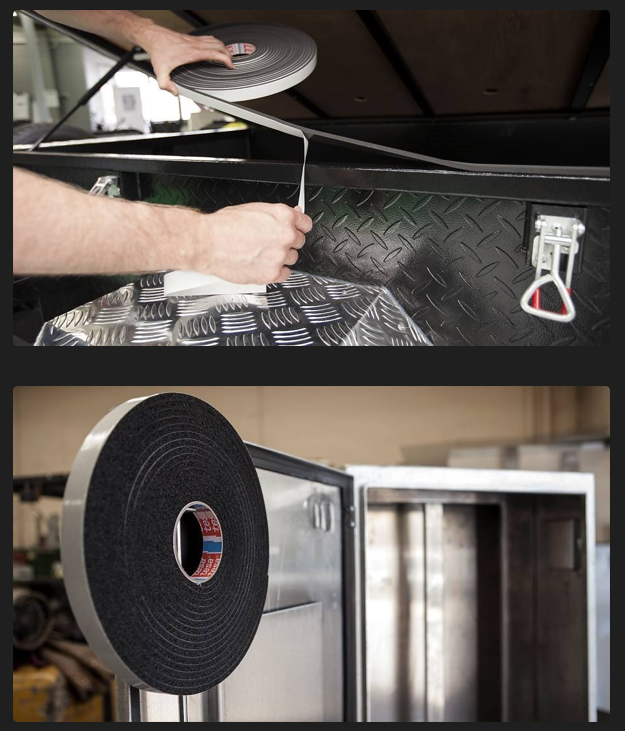

If you are after individual rolls, we have the Stylus HBF - High Bond Foam range available

For larger quantities, we have the full 3M VHB - LSE Tape range available

We supply Double Sided Tape for "Hard To Stick To Plastics" - Low Surface Energy (LSE) Plastics Australia Wide